Key Takeaways

- Bilge pumps are crucial for removing minor water ingress but are not substitutes for addressing significant leaks or hull breaches.

- Regular maintenance, including cleaning and testing, ensures bilge pumps function effectively.

- Modern bilge pumps feature automatic activation and oil detection capabilities to enhance safety and environmental protection.

Understanding Bilge Pumps

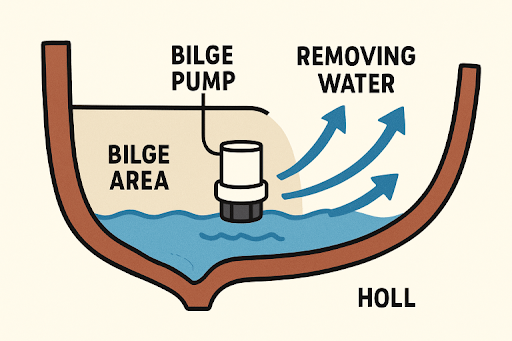

Maintaining a dry bilge is crucial for maritime safety, as bilge pumps are essential for removing water that accumulates in the lowest part of a vessel due to rain, waves, or leaks. Efficient removal of this water is vital for the comfort, stability, and safety of the boat. The bilge area, which collects water and debris, can affect floatation and lead to corrosion issues. To keep everything running smoothly, components like bilge pumps and the necessary hardware, such as a Groco strainer replacement part, play a crucial role in ensuring that the system operates consistently and efficiently.

The number and placement of bilge pumps depend on the boat’s size and design. Smaller boats typically require one pump, while larger vessels may need multiple pumps, positioned at low points. Bilge pumps are designed for ordinary maintenance and are not intended to replace permanent repairs or handle significant breaches. Regular monitoring of water accumulation is essential to prevent overwhelming the pump.

Limitations of Bilge Pumps

Despite being dependable safety devices, bilge pumps have apparent limitations. It’s a common misconception that bilge pumps can save a boat suffering from a significant leak or hull breach. In fact, when a pump is faced with copious water from events such as a ruptured skin fitting, a mechanical seal failure, or a large crack below the waterline, it is quickly overwhelmed. This underscores the reality that even the most efficient bilge pumps are not substitutes for prompt and permanent repairs. Consistently allowing water to linger in the bilge poses other risks besides immediate instability. Lingering moisture can accelerate hull and engine corrosion and create the ideal environment for osmotic blisters in fiberglass structures. In excessive cases, ignored water ingress can ultimately lead to loss of flotation and sinking.

Proper Use and Maintenance of Bilge Pumps

Like any onboard equipment, bilge pumps and their components require consistent attention to function reliably. Routine maintenance includes both cleaning and operational checks. Start by inspecting the pump and surrounding area for trash, algae, or loose objects that could compromise the intake or cause clogs. Ensuring that the float switch moves freely and isn’t corroded or ensnared by debris is key, since a malfunctioning switch could leave standing water where you don’t want it. Wiring also demands scrutiny—route wires upward and away from standing water, use marine-grade electrical connectors, and check for corrosion at every joint. A best practice is to test the bilge pump before every outing and periodically while at the dock. Replacing worn or faulty hardware, such as strainers and float switches, can prevent minor problems from developing into serious hazards.

Environmental Considerations

Many boaters are now more conscious of the potential environmental impact of discharging bilge water into rivers, lakes, or coastal areas. As water collects in the bilge, it can mix with small amounts of engine oil, fuel, or even cleaning agents. Releasing this mixture is not only harmful to marine life but is illegal in many jurisdictions. To mitigate contamination, absorbent pads specifically designed for oil and fuel can be placed in the bilge. These will capture leaks before they mix with pump-discharge water. It’s essential to inspect the water in your bilge regularly, removing and disposing of contaminated absorbents properly before running the pump. Avoid using detergents or “miracle” bilge cleaners that claim to break up oil; these often only disguise the issue while making cleanup and compliance even more difficult.

Advancements in Bilge Pump Technology

Recent decades have witnessed significant advancements in bilge pump design, with a focus on safety, efficiency, and environmental protection. Some pumps now include automatic sensors that activate when water reaches a preset level, ensuring pumping begins even if the owner is distracted. Other advanced models feature oil and fuel detection sensors: if these pollutants are detected, the pump automatically halts, preventing contaminated water from escaping into the environment. These modern systems may also integrate alarms to provide both auditory and visual warnings, alerting boaters to the presence of water, contamination, or pump failure. Advanced wireless monitoring can even send alerts to a captain’s mobile device, allowing for immediate action and minimizing both damage and pollution risks. Continual advancements enable boaters to more effectively manage bilge water and fulfill their duty as stewards of the environment.

Conclusion

Bilge pumps stand as one of the foundational safety tools on any vessel, providing vital management of everyday water ingress. However, the security they provide is only as reliable as the preventative maintenance and proper usage habits upheld by the operator. They cannot compensate for neglecting major repairs, nor can they disregard the responsibility of reducing environmental harm. Adhering to a disciplined maintenance schedule, regularly inspecting for contaminants, and using the latest pump solutions that incorporate technology for enhanced safety and compliance all ensure that you, your passengers, and the waterways you enjoy remain safer for everyone. Those who boat with a preparedness mindset—bolstered by thoughtful care of their bilge systems—demonstrate leadership and stewardship on and off the water.