Key Takeaways

- Pad printing enables precise decoration on a wide variety of materials and geometries, supporting advanced manufacturing requirements.

- The medical, automotive, and electronics industries use pad printing for durable, high-quality imprints that enhance safety and product aesthetics.

- Technological innovations are transforming pad printing, driving greater efficiency and advanced design capabilities.

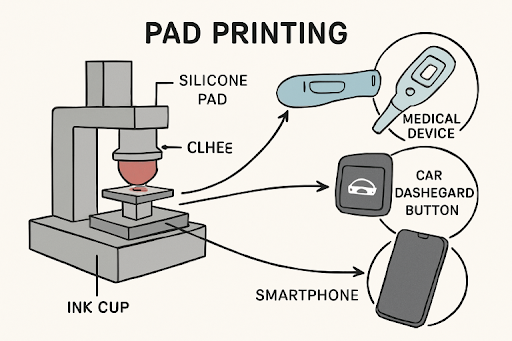

Pad printing has become an essential process within contemporary manufacturing, empowering industries to achieve unmatched accuracy and consistency in branding, identification, and aesthetic enhancement. This unique printing technique excels at applying detailed images, logos, and markings to surfaces that are traditionally considered difficult to print upon—such as curved, textured, or irregularly shaped objects. For manufacturers seeking a versatile approach to product decoration, adopting advanced pad printing equipment is closely tied to both product quality and operational throughput. With over three decades of experience, Diversified Printing Techniques has established itself as a trusted authority and supplier in the pad printing sector. Their extensive portfolio, which includes state-of-the-art machines and custom automation solutions, positions them as a go-to resource for businesses across industries like medical devices, automotive components, and consumer goods, with a strong service presence throughout the United States.

This article explores innovative uses of pad printing in today’s manufacturing landscape, highlighting its direct impact on industry standards, product appeal, and regulatory compliance. Read on to discover how advancements in technology and process efficiency are pushing the boundaries of what pad printing can achieve, ensuring top-tier results for product designers and manufacturers.

Enhancing Medical Device Manufacturing

Accuracy and safety are absolute priorities in the medical industry. Pad printing delivers legible, wear-resistant markings to instruments such as syringes, catheters, and surgical implements, which are essential for identification and safe clinical use. The non-contact application reduces the risk of contamination, and the compatibility with medical-grade inks supports sterility. Automated pad printing systems, with greater speed and repeatability, help device manufacturers meet increasing demand while complying with international health regulations. In practice, implementing computerized solutions improves traceability and helps prevent costly manufacturing errors. For more insights into regulatory impacts on medical device labeling, visit the comprehensive overview from the U.S. Food & Drug Administration.

Advancements in Automotive Component Labeling

The automotive sector relies on pad printing for both aesthetic and functional component labeling. Whether it involves dashboard symbols, climate controls, gear indicators, or warning icons, the markings must remain vivid and durable, even under harsh conditions such as high humidity, rapid temperature shifts, and prolonged ultraviolet exposure. Automated pad printing stations have dramatically increased efficiency for high-volume automotive suppliers by standardizing outputs and minimizing misprints that lead to costly scrappage. These efficiencies are crucial for just-in-time production strategies that dominate automotive supply chains. Reliable markings contribute not only to user safety but also to the brand integrity of the vehicle manufacturer.

Precision in Consumer Electronics

The consumer electronics industry thrives on visual impact, miniaturized branding, and intricate graphical details. Pad printing stands out for its ability to transfer high-resolution artwork onto challenging surfaces, such as smartphone bezels, smartwatch backs, and gaming controller buttons. Manufacturers leverage this flexibility to prototype new designs rapidly, respond to changing trends, and roll out customized product variants. One of the leading challenges—maintaining consistency across thousands of units—is addressed by integrating automation and advanced plate technologies, resulting in immaculate results that do not degrade over time. For additional perspective on design trends in consumer electronics, consult WIRED’s Gear section for its design coverage.

Innovations in Pad Printing Technology

Significant technological progress has redefined what is possible with modern pad printing techniques. The adoption of laser-engraved printing plates, for instance, has increased both the precision and longevity of print runs. These plates surpass traditional photopolymer equivalents by enabling higher image resolution and faster setup times, which are essential for industries handling high-mix, low-volume product lines. Another milestone is the merging of digital inkjet and pad printing workflows, facilitating complex color gradients, photographic elements, and multi-layered graphics that appeal to design-focused sectors. These integrations are instrumental in reducing waste, shortening production cycles, and increasing flexibility for clients with bespoke graphic requirements.

Pad Printing in Promotional Products

In the advertising specialty and promotional goods market, rapid turnaround and quality consistency are paramount. Pad printing, such as that from Diversified Printing Techniques, meets these needs by accommodating mass production of logoed items like pens, keychains, mugs, and USB drives. Suppliers who rely on this method cite the ability to maintain sharpness and color fidelity even on very small or unconventional shapes, thus enhancing their value proposition to end clients. By supporting diverse material substrates—plastic, metal, glass, or ceramic—and short lead times, pad printing allows brands to maximize market reach and campaign effectiveness. This versatility is why many promotional product distributors seek high-throughput pad printing equipment to stay competitive.

Environmental Considerations and Sustainability

Environmental responsibility is increasingly important in manufacturing, and pad printing technology continues to evolve to reduce its ecological footprint. Modern printers use energy-efficient servo motors, reclaim solvents, and operate with water-based or low-VOC inks to curb emissions and workplace exposure. Custom ink formulations now achieve high adhesion and coverage with significantly less waste. Manufacturers are also adopting recyclable or biodegradable substrates where possible, extending the sustainability of printed goods. This commitment aligns with broader trends toward circular-economy models and the reduction of industrial waste streams.

Conclusion

As technological advances unlock new dimensions for product design and efficiency, pad printing is firmly positioned at the heart of modern manufacturing innovation. Its reputation for versatility, precision, and adaptability secures its ongoing role in diverse sectors. Brands and manufacturers that invest in the latest pad printing solutions, such as those from Diversified Printing Techniques, are well-equipped to meet evolving market and regulatory demands with confidence and creativity.