Smart manufacturing and operations have been on the rise for a while and is mainly driven by IoT. Deloitte regularly surveys enterprise management for their views and plans for the future in relation to technology, its challenges and opportunities. According to Deloitte’s recent survey published on May 1st, 2025:

“92% of manufacturers believe that smart manufacturing will be the main driver for competitiveness over the next three years.”

To incorporate this, a professional IoT development company can provide IoT services including embedded systems, data gathering and processing, data analytics, and cybersecurity. According to the same survey, building smarter operations is often done to achieve two key goals:

- 49% of executives seek operational benefits,

- 44% aim to achieve financial benefits.

Deloitte further reports that operational benefits from smarter operations include:

- an up to 15% increase in capacity,

- a 7% to 20% productivity boost, and

- a 10% to 20% improvement in manufacturing yield.

In addition to that, IoT developments, when used to create smarter operations, lead to changes in the business model. For instance, servitization is the concept of transforming one-time sales of equipment into a subscription-based service. Instead of a one-off sale, the equipment is enhanced with sensors that track its usage, and the manufacturer bills monthly based on it. It creates a win-win situation for both the manufacturer and the buyer. The manufacturer enjoys stable income while buyers mitigate the risks of not getting the value out of the investment, while also not having to incur the full cost at once. As such, IoT enables servitization that is becoming widely adopted and forms a new competitive strategic advantage for smart operations. In addition, simply a move from product-only to product-service model also falls within servitization.

Introducing IoT for industry

IoT for industry has already ingrained itself into several key functions. An IoT development company’s services list generally includes predictive maintenance, IoT for energy savings, real-time monitoring, and incorporating IoT across the supply chain. Here are some examples:

- Manufacturing facilities install sensors to detect heat and vibration on robotic arms to schedule predictive maintenance.

- IoT thermostats at cooling facilities maintain the required temperature levels while minimizing energy use.

- In the medical field, real-time sensors for temperature and humidity are utilized to monitor the conditions of cleanrooms.

- Retailers often use sensors such as RFID pallets and smart shelves to ensure stock levels.

For each of these, there are hardware and software parts that enable control and monitoring. Therefore, each IoT system is provided with a custom app by an IoT app development company. For example, a predictive maintenance app will have a dashboard showing “health” levels for the monitoring equipment, might issue alerts when a piece of equipment requires a service, and allow the operations manager to schedule maintenance based on the data from sensors.

For servitization, the software part in the form of an app is even more essential. For instance, instead of selling compressors, a company provides a compressed-air-as-a-service model. The manufacturer provides the equipment, its setup and maintenance, and bills the client the base monthly subscription plus usage fee. Or, for instance, instead of selling or leasing delivery vans, the company provides cars on a pay-per-use basis. In all cases, the business model implies installing custom sensors and connecting them to a custom app, which will be the basis for tracking usage and billing.

See how IoT is being used by real businesses

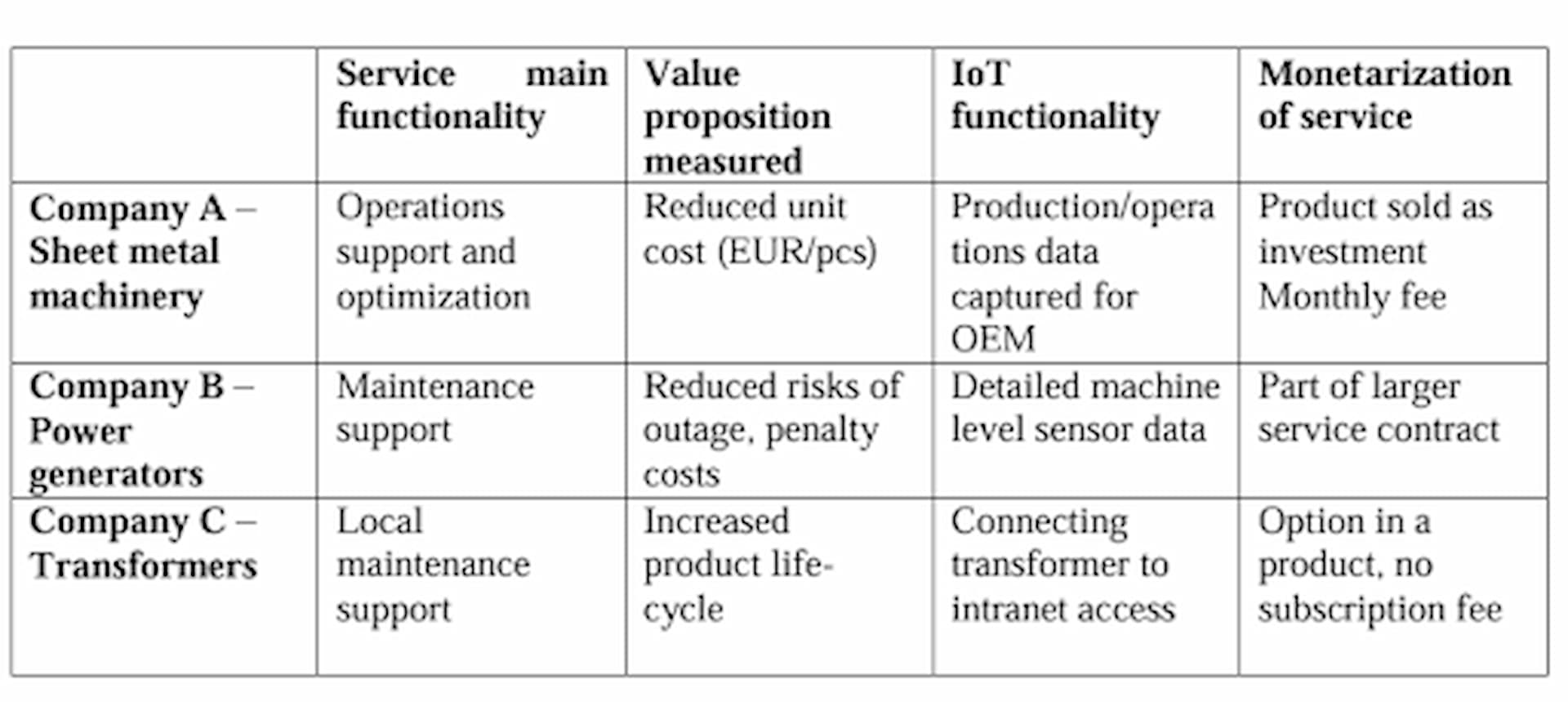

IoT-enabled servitization is enacted across different industries. Here are case studies as described in academia that fall within the scope of capabilities of an IoT software development company. These are based on the examples of real global companies that first established themselves as product-oriented and now are shifting towards product-service orientation.

Company A still sells the same equipment, but it is enhanced by IoT sensors that provide vital insight for the customer. The product is sold as an investment, and there is also a monthly fee for remote support. The other added bonus is staying in regular contact with the customer.

Company B is introducing a product-service model by using IoT devices for Condition-Based Maintenance. The IoT role is mainly linked to ensuring the target output of power generators.

Company C decided to incorporate IoT sensors in transformers for power generation and targeted three areas: maintenance, operations, and data.

Implementing IoT in your business

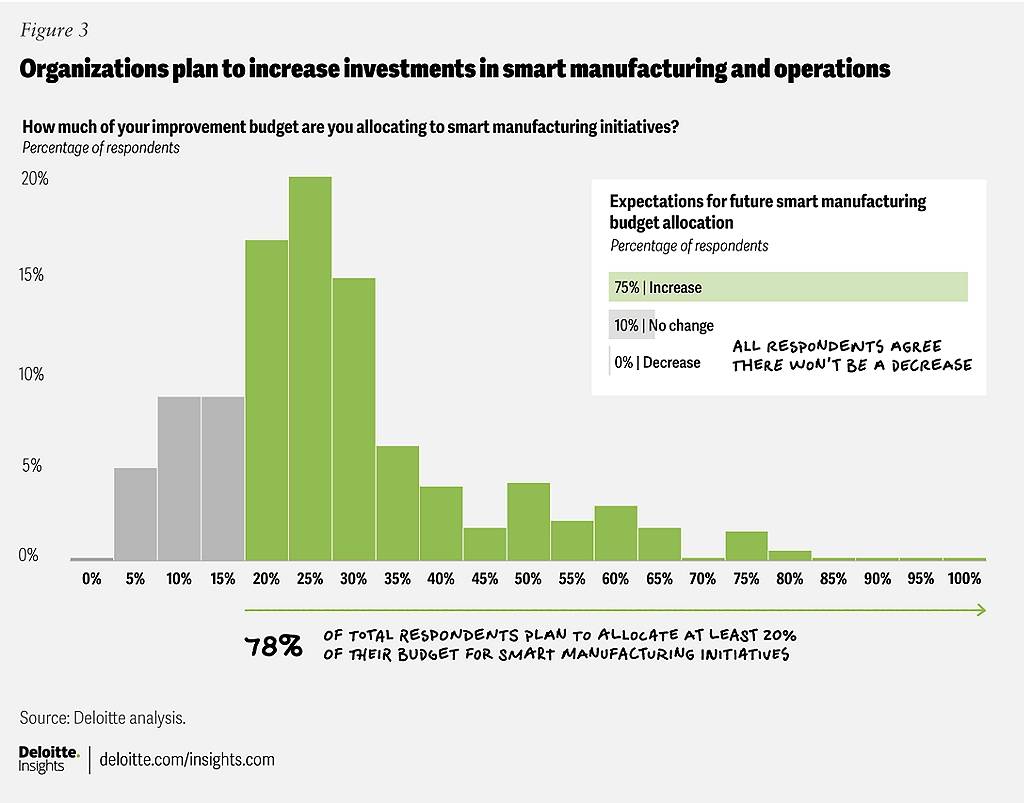

Manufacturers and other businesses take transformation into smarter operations in increments. It is important to recognize that budgets for smart manufacturing initiatives are increasing for the majority, and no one is expecting them to decrease. Therefore, bringing in an IoT development company is inevitable, as each initiative requires expert input. Eventually, there is likely to be a need to integrate various initiatives into one smart manufacturing app.

Steps of implementing an IoT system for smart operations are outlined in the table below.

| Step1 | Groundwork to identify areas for IoT with the highest business/strategic value | Operations are often complex and modular; therefore, a particular section of operations often plays a limited role in the final product. In addition, some operations will seek direct financial goals while others prioritize productivity increases, capacity expansion, or enhanced quality control. |

| Step2 | Sourcing an IoT application development company for custom work | This company takes on the design and implementation of the system, including hardware and software. A professional company will always prioritize security and scalability when it comes to industrial IoT solutions. |

| Step3 | Interpreting Insights from the Smart Operations System | The above-mentioned company might also provide services for interpreting and processing the data coming from the devices. This step might involve polishing the software and training your personnel to work with it. |

| Step4 | Continuous Support and Optimization | When an IoT system becomes a part of daily routine, your staff and managerial personnel might see more opportunities for optimization and new insight. At this stage, iterative updates increase systems’ efficiency. |